In construction, efficiency and precision are vital to project success. One area where these qualities can be enhanced is in the process of placing materials orders. By leveraging the data and insights from your takeoff and estimating plans, you can revolutionize the way you order materials for your construction projects. There are numerous benefits of placing materials orders directly from your takeoffs. We’ve highlighted a few of the advantages of this approach, including streamlined ordering, cost savings, and enhanced project coordination. We’ve also included steps on how to place a partial order with Takeoff Monkey.

Placing materials orders directly from your takeoff and estimating plans streamlines the entire ordering process. With accurate takeoff data at your fingertips, you can easily identify the exact quantities and specifications of materials needed for each stage of the project. This eliminates guesswork and reduces the time spent searching through catalogs or consulting with suppliers. By directly translating plans into products, you can expedite the ordering process, ensuring that the right materials are available when needed, and reducing delays on-site.

Ordering materials based on your takeoff and estimating plans helps eliminate waste and unnecessary overstocking. By precisely calculating the quantities required, you avoid overordering, which can lead to surplus materials and wasted resources. Furthermore, accurate takeoffs enable you to identify materials with longer lead times, allowing you to order them well in advance, avoiding supply chain delays, rush orders and premium prices. By optimizing your materials procurement, you can save costs and maximize your project’s budget efficiency.

Placing materials orders from your takeoff plans promotes better project coordination. By aligning your orders with the project schedule, you ensure that materials are delivered when they are needed, avoiding bottlenecks and keeping construction progress on track. This synchronization enhances communication and collaboration among project stakeholders, allowing for smoother workflow management and reducing the chances of delays caused by material shortages.

Ordering materials directly from your takeoff/estimating plans helps minimize miscommunications and errors. When you rely on accurate takeoff data, you can confidently provide suppliers with detailed information, such as product codes, dimensions, and quantities. This clarity reduces the risk of misinterpretation, ensuring that the materials you receive precisely match your project requirements. By eliminating errors in material orders, you avoid costly returns, replacements, and disruptions to construction activities.

Takeoff Monkey simplifies the process of partial material ordering during construction, making it easier than ever to optimize your material procurement. These orders are often high pressure with not a lot of time to pull the order together, and it must be complete.

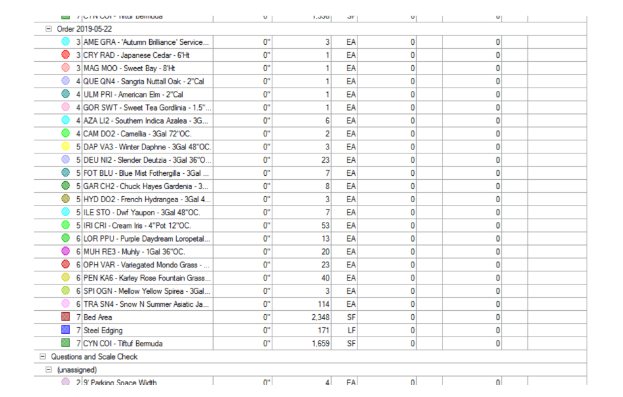

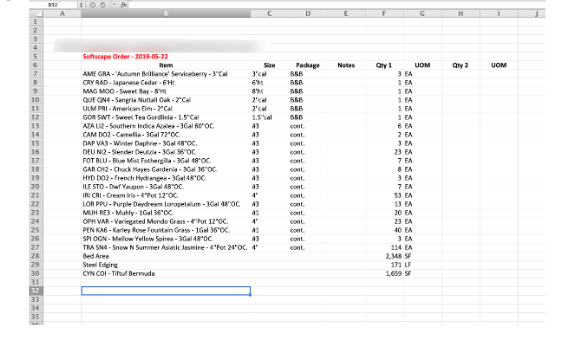

Partial orders require someone to sit down and manually count individual items one by one. This can take hours. Turn a lengthy counting process into a simple swipe of your client’s finger or pen with these three steps:

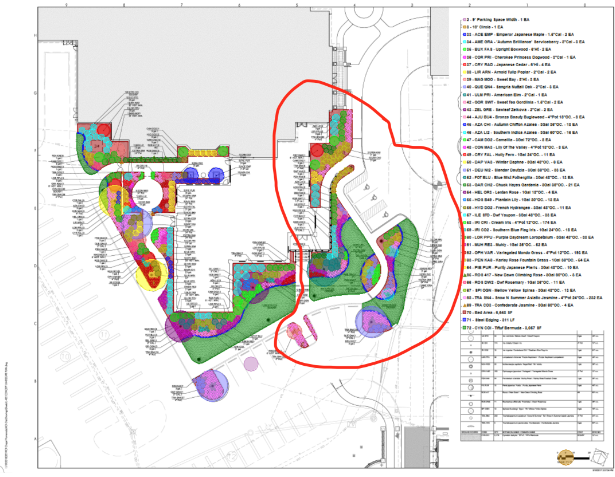

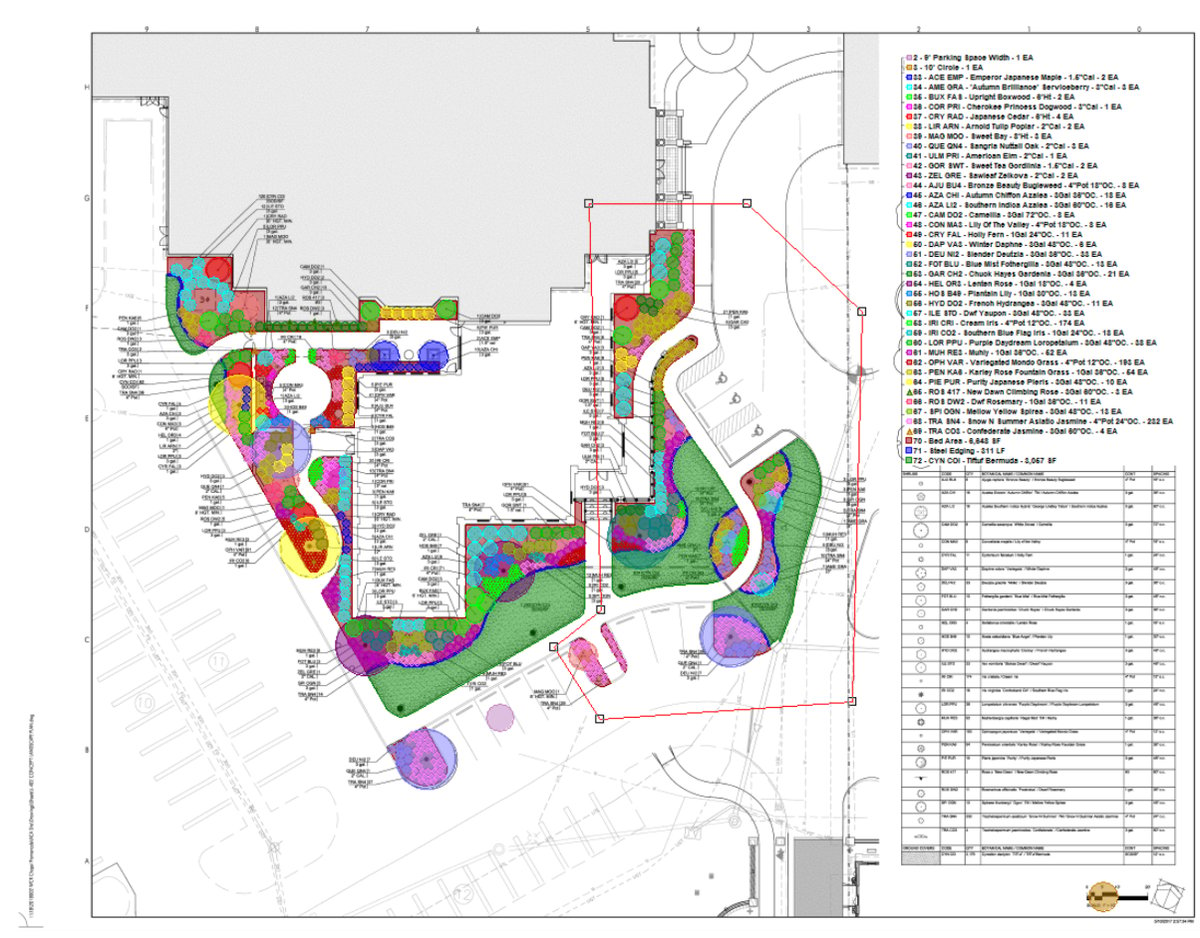

Your customer simply opens their plans or completed takeoff, and circles the part of the project they need to complete. Literally takes seconds. They can do this digitally or with pen and paper and snap a photo. Customers can make many circles, on as many sheets as necessary to complete all the areas and scopes required. We ask that all boundaries have closed borders.

Send your client’s partial order to Takeoff Monkey (either by email, our website or via your own customizable bid board), and we’ll recreate their exact boundaries in our software. This also takes mere seconds.

We can now isolate only the items inside these new boundaries, and we’re done! You’ll have a new tab in your materials worksheet with their order. The takeoff worksheet is now a working document so you can keep record of the project’s progress all in one place.

This innovative approach allows you to order materials in smaller quantities as the project progresses, rather than making bulk purchases upfront. By tailoring your orders to match the specific needs of each construction phase, you can optimize your inventory management. This strategy minimizes storage requirements, reduces the risk of material damage or theft, and improves cash flow by avoiding excessive upfront expenses.

It’s like having a magic wand that conjures up just the right amount of materials at the right time. Get in touch with our team today to hear how Takeoff Monkey can greatly reduce the time you spend on material orders.